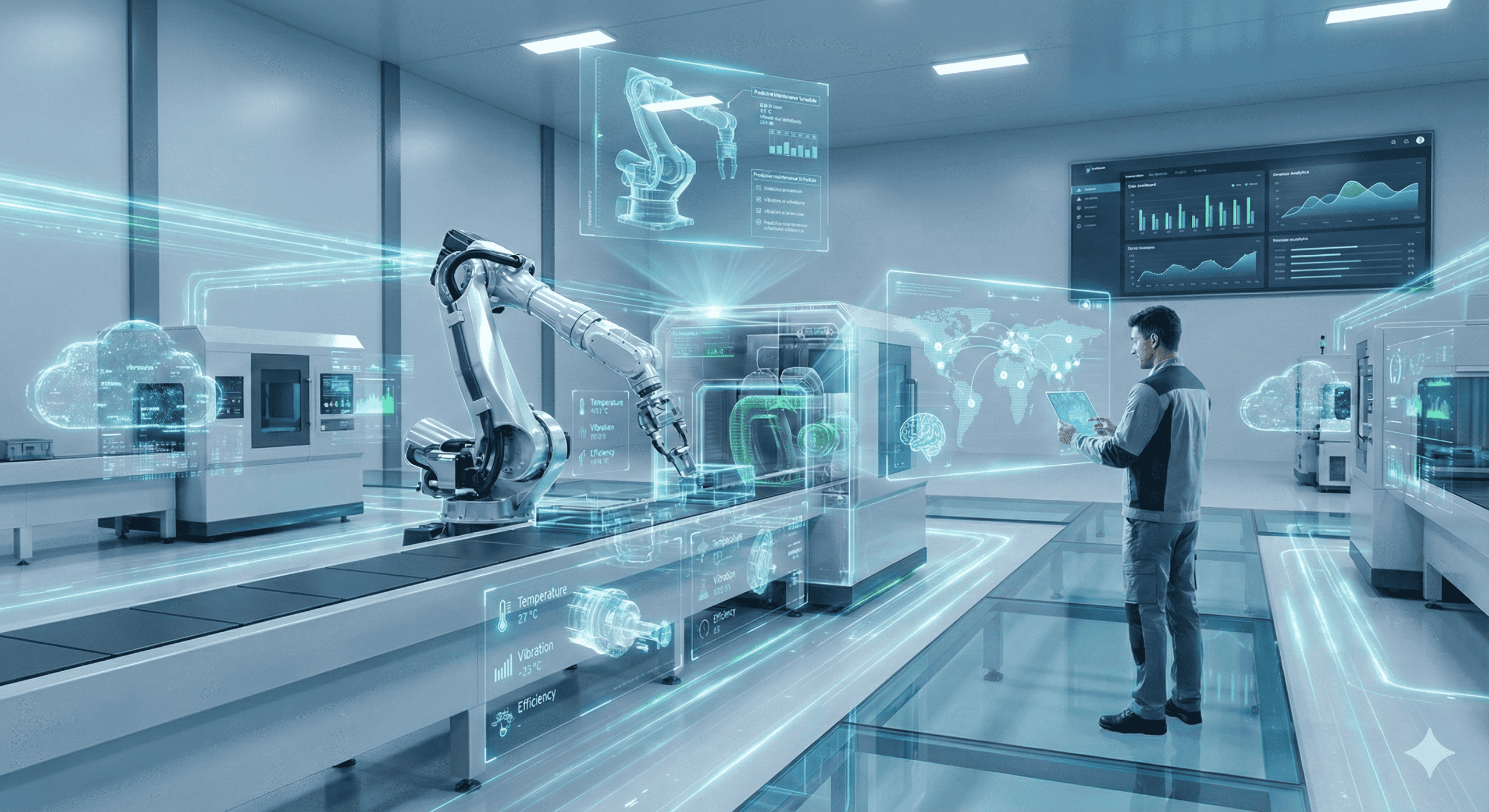

Industry 4.0 and Smart Manufacturing in 2026

Embrace the future of manufacturing in 2026 with Industry 4.0. Learn how smart automation and predictive maintenance can transform your operations today!

Embrace the future of manufacturing in 2026 with Industry 4.0. Learn how smart automation and predictive maintenance can transform your operations today!

Transform your facilities management with CMMS software. Optimize building maintenance and enhance property management efficiency effortlessly today!

Uncover the key differences between building management and facility management. Learn definitions, roles, and how each impacts your properties effectively.

Learn what facility management is and why it’s crucial for effective building operations. Explore essential insights into best practices and software solutions.

The Industrial Renaissance of 2025: A Comprehensive Analysis of Manufacturing Transformation Executive Summary: The Convergence of Intelligence, Resilience, and Human Potential The global manufacturing sector in

If you are running a manufacturing plant, managing a complex fleet, or overseeing facility operations today, you likely feel a shift in the air. It’s not

CMMS and the New Maintenance Manager: A High-Stakes Partnership Stepping into a new role as a maintenance manager can feel like trying to fly a plane

Facility Management in 2026: Navigating Transformation and Taking the Lead Introduction The facility management landscape is changing faster than ever before. With the arrival of 2026,

Grow Smarter — Making Space Work Harder for Your Organization Rethink growth beyond square footage When companies talk about growth, the immediate image is often

Why Every Business Needs CMMS: Real-World Benefits and Tips for Implementation Let’s be honest: keeping up with equipment, maintenance schedules, and surprise breakdowns is a

The Rise of AI in CMMS: Trends and Benefits for 2025 Maintenance managers and engineers in industries like manufacturing, healthcare, and facilities management are turning to

Why MicroMain CMMS is the Game-Changer Your Business Needs The Power of Effective Maintenance Management For CEOs and decision-makers in manufacturing, healthcare, education, or hospitality,

As industries evolve, so do the technologies that support maintenance management. Emerging trends such as predictive analytics, artificial intelligence, and mobile applications are transforming how organizations approach maintenance. These technologies not only enhance efficiency but also enable proactive decision-making, allowing teams to address potential issues before they escalate.

For instance, predictive analytics can analyze historical data to forecast equipment failures, while mobile applications empower technicians with real-time information on-the-go. Companies that adopt these trends can significantly reduce downtime and maintenance costs, positioning themselves ahead of competitors who rely on traditional methods.

Effective training is crucial for the successful implementation of a CMMS. Best practices include hands-on training sessions, regular workshops, and the creation of comprehensive training materials that cater to different learning styles. By investing in training, organizations can ensure that their maintenance teams are well-equipped to leverage the full capabilities of the software.

For example, incorporating real-life scenarios into training can enhance understanding and retention. Additionally, ongoing support and refresher courses can help maintain high levels of proficiency, ultimately leading to improved operational efficiency and user satisfaction with the CMMS.

Understanding the differences between Computerized Maintenance Management Systems (CMMS) and Enterprise Asset Management (EAM) is essential for businesses looking to optimize their maintenance strategies. While both systems aim to improve asset performance, CMMS focuses primarily on maintenance tasks, whereas EAM encompasses a broader scope, including asset lifecycle management and financial considerations.

Choosing the right system depends on the specific needs of the organization. For instance, a manufacturing firm may benefit from a CMMS to streamline maintenance operations, while a large enterprise might require an EAM solution to manage a diverse range of assets across multiple locations. Evaluating the unique requirements of your business will help in making an informed decision.

Data analytics plays a pivotal role in refining maintenance strategies by providing actionable insights into equipment performance and maintenance activities. By analyzing data collected through CMMS, organizations can identify patterns and trends that inform better decision-making and resource allocation.

For example, data analytics can reveal the most common causes of equipment failure, enabling maintenance teams to address underlying issues proactively. Companies that leverage data analytics not only enhance their maintenance processes but also drive continuous improvement, leading to increased operational efficiency and reduced costs over time.